1140V-10kV

Mine explosion-proof and intrinsically safe high voltage (permanent magnet synchronous) frequency conversion and speed regulation machine

INTRODUCTION

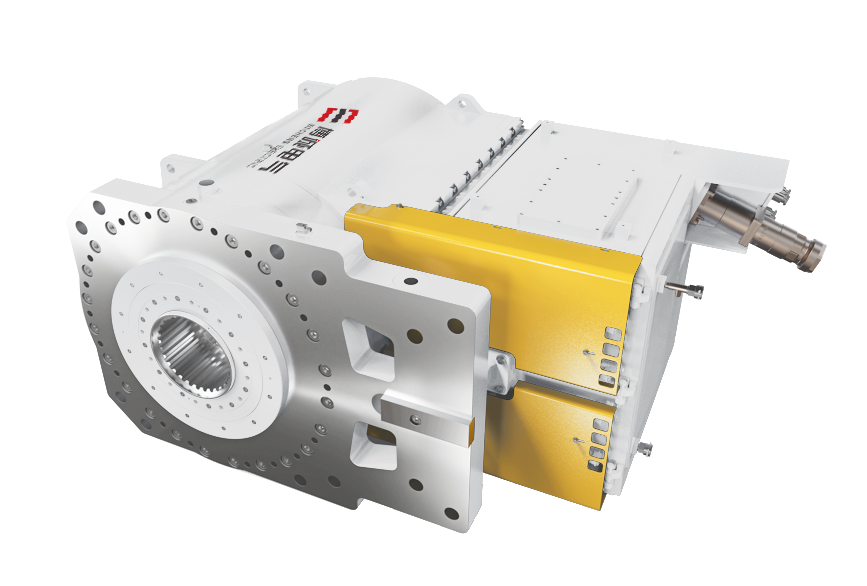

The intelligent permanent magnet frequency conversion hybrid drive system represents an upgraded and evolved version of the permanent magnet frequency conversion integrated motor system. It has been specially designed to meet the dimensional requirements of on-site usage, featuring a high level of integration with high-efficiency permanent magnet motors, inverters, and planetary wheel reducers. This system stands as a cutting-edge, next-generation intelligent hybrid drive integrated machine product In addition to retaining the advantages of the VF speed regulation integrated motor, the external dimension is smaller and the scope of application is larger.

The Bocheng Electric's Intelligent Permanent Magnet Frequency Conversion Hybrid Drive Integrated Motor has the characteristics of small size, high reliability, high overload capacity, high heavy load startup, etc., thereby gradually replacing the original drive equipment in more and more integrated transportation systems.

APPLICATION FIELD

Coal industry

Pharmaceutical industry

Power industry

Port industry

Petroleum industry

Metallurgical industry

Marine industry

Water industry

Water industry

Cement industry

Chemical industry

Urban rail transportation industry

Rubber industry

Pipeline transportation industry

TECHNICAL ADVANTAGE

Intelligent

Automatic diagnosis: abnormal working conditions of the equipment caused by changes in the external environment can be found in time and adjusted accordingly;

Remote monitoring: real-time communication and monitoring between the site and the backstage, as well as unified management by the upper level control system;

Multi-machine collaboration: automatic load balancing;

Autonomous speed control: material flow monitoring system may be installed to realize automatic speed control of the integrated motor;

Remote diagnosis: 5G/Wi-Fi communication, seamless access to the DCS system, and early warning based on the collected operational data subjected to problem analysis and diagnosis of remote big data modeling.

Energy conservation

High power factor: use high power factor Permanent Magnet Synchronous Motor, no excitation or rotor copper loss, and improve the energy efficiency of the motor;

Outstanding Dynamic Response: Intelligent motor control operates the motor in real-time to maintain stability and optimize system efficiency according to the actual operational conditions.

Excellent performance

Low impact: the starting current is controllable during load startup, eliminating the impact on the power grid;

Large torque: large starting torque at load startup, direct maximum torque output at heavy load startup;

High stability: small vibration and low noise of the system, and high operation stability;

Wide range of speed control: 10-1500 revolutions per minute, it meets the full spectrum of system speed adjustment needs;

Space saving: the combination of the Permanent Magnet motor and the inverter reduces volume and saves space and reduces the cost of chamber construction.

Low maintenance cost

Long service life: The system boasts a straightforward design, and the motor is purposefully crafted for variable frequency operations, ensuring an extended lifespan.

EQUIPMENT SELECTION TABLE